Moving Propeller Alert System – Self Contained, Economical Version – Senior Design Project

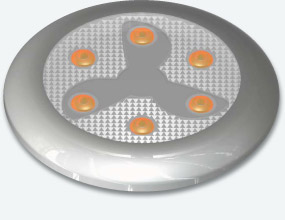

This design project is a self contained, self powered, warning module that lights or blinks LED lights off the stern when the outboard or stern drive engine is running to warn people in the water to stay out of the propeller danger area.

Earlier today (30 November 2011) we posted coverage of Mercury Marine’s new Moving Propeller Alert System that plugs into their CAN-bus SmartCraft system to alert those in the water the drive is running in neutral, or the propeller is turning. When we saw retrofit costs for parts alone were $315.68 per drive we started thinking about a more economical, self contained module that could work for single or multiple drives.

We propose further design by students as Senior Design Projects, Sr. Thesis, Industrial Design, and Capstone projects of a rugged, economical, self contained version of Mercury’s Moving Propeller Alert System that could monitor one or more engines/drives from a single module and offer suggestions for same.

This design project might especially appeal to students studying design, electrical engineering, computer science, mechanical engineering, safety, industrial design, human factors, marine engineering, and ocean engineering.

Mercury flashes their Moving Propeller Alert when the drive is started, then leaves it on steady up to 2,000 rpm at which time it turns the lights off. While we can envision the flashing lights being very helpful if they were flashed for several seconds before the engine was started, once the engine is started and the drive is in gear, its too late for those in the water up close to the boat. It still could be useful to flash the lights the first several seconds after the engine is started, then shift to a continuously being on.Mercury Marine, the rest of the industry, and several boating safety groups say drives that are running in neutral are dangerous and should not be approached. They are saying the same thing our dad’s told us about guns, “Treat every gun like it is loaded.” Their equivalent message is “Treat every drive in neutral like it is in gear.” If you elect that approach, you only need two positions for the lights (Off, On) in which the On might be a rotating pattern like Mercury uses to signify the drive is in gear.

We first thought of creating a hockey puck looking potted brick containing a battery, the electronics, and the LEDs. It could be designed to detect hull or drive vibrations to determine if the engine was on, then turn the lights on as appropriate. Being battery powered, LED lights consume little power, the system might be designed to last a boating season. If economical enough, it could be thrown way, and replaced each year.

Then with a little more thought, we turned to solar power. Most boating is done on nice days, or at least in the daylight. Why not power the LEDs with a small solar cell array? Surplus power could be used to charge a small battery to run the lights when it was dark. We previously noticed a lighted waving American Flag sign for vehicle windows using this approach on Shark Tank (TV show where entrepreneurs pitch their ideas to investors).

Next our minds turned to sensing the hull vibrations to determine when to turn the lights on, and the light came on in our heads instead. Why not power the lights by hull vibrations, similar to movement powered wrist watches and shake flash lights?

For example, the Forever Flashlight uses Faraday’s Principle of Magnetic Induction to pass a magnet through a metal coil to charge a capacitor per their description on Amazon. Others are harvesting energy from random vibrations by using stacks of pizeoelectrics.

Elements of the Moving Propeller Alert System Design

The project includes several design elements:

Detecting the engine is running – This could be done by affixing your module some rigid part of the boat and detecting vibrations (make sure waves can’t set it off), by listening for the engine (make sure other boats nearby don’t set it off), by sniffing exhaust fumes at the stern (make sure other boats don’t set it off), or by some other means.

Detecting the propeller is turning – we feel the sensor would be satisfactory if it did not detect the propeller being in gear even though the Mercury version does. If you do elect to detect the boat going in gear, you might be able to detect the drive shift clunk, pickup a change in hull vibrations, view the water movement to the stern, or detect some other variable.

Power Source – battery, solar, vibration, heat powered (its hot back there in some places), or some other source.

Turn off lights above 2000 RPM – might not be needed if vibration powered. The faster you go the more vibration power you create. You could probably sense higher RPMs from the hull vibrations as well if needed, but they might vary by boat. Of you might just turn the lights off after they have been on for 5 minutes or so, then recycle the system every time the hull vibrations stop.

Mounting System – Mercury mounts theirs in a navigational light socket. If you are going to use vibrations as an input and to power the unit, you will need to be pretty tightly bound to the hull. A holder with a socket for the module might be glued to the hull. That would allow you to replace the module if needed without replacing the holder. But the industry might be leery of sticking anything on fiberglass hulls. You might be able to work from a light socket like Mercury or from some other standard piece on a hull (like a special cleat, etc.) Or you might stick it directly on the drive.

Logic System – Just decide what you want to do and design it.

Marine corrosive environment protection – the system will be in a wet, hot, humid, vibrating, sunny, corrosive environment that may even take some fuel or oil spills. It will need properly designed.

Cost control – the idea is to keep costs low while maintaining the ability for one module to do the work of several on multiple drive boats.

Bibliography

We offer a brief bibliography you may find helpful.

- Mercury Marine’s new Moving Propeller Alert System our post.

- Study of Broad Bandwidth Vibrational Energy Harvesting System With Optimum Thickness of PET Substrate. Pan, Liu, and Chen. Current Applied Physics. 13 pgs. Not yet published. Available on Science Direct / Elsevier. They harvest ambinet vibrational energy to flash an LED.

- Design of Low Power VLSI Systems Powered by Ambient Mechanical Vibration. Rajeevan Amirtharajah. MIT. June 1999. Phd Thesis.

- Machinery Condition Monitoring Using Wireless Self-Powered Sensor Nodes. Discezo, Loparo, Cassar, and Chung. Describes shipboard systems that harvest energy then relay machinery status information. This paper is available free online.

- Self-Powered Sensors for Monitoring of Highway Bridges. Sazonov, Li, Curry, and Pillay. Sensors Journal. IEEE. Vol.9, (2009) Pgs. 1422-1429. This paper is available free online.

- A flex-compressive-mode piezoelectric transducer for mechanical vibration/strain energy harvesting. LI X, Guo M., Dong S. IEEE Transactions on Ultrasonics, Ferroelectrics, & Frequency Control. Vol.58. No.4. April 2011. Pgs. 698-703.

- Toward Broadband Vibration-based Energy Harvesting. Lihua Tang, Yaowen Yang, and Chee Kiong Soh. Journal of Intelligent Material Systems and Structures, Dec 2010; 21: 1867 – 1897.

- U.S. Patent 7,927,292 Self-powered Vibration Sensor. Stephen Brown. Transforms vibrations into RF pulses which are recorded and manipulated.

- U.S. Patent 7,247,063 Warning Device for Marine Engines for Small Craft. Marc Lemchen. Detects rotating propeller and warns those in the water.

- U.S. Patent 6,969,287 by Motsenbocker. Electronic marine drive with sensors to detect people in the danger zone and stop the prop.

Search Terms

Those who elect to look for more specific resources may find these search terms helpful.

- Ambient mechanical vibration / ambient vibration

- Self powered

- Energy scavengers

- Power harvesting devices

- Energy harvester

- Vibrational energy

- Kinetic energy harvester

Updates

9 October 2013 – we noticed an entry called “EchoCharge” won first place in the Graduate Division of the Donald W. Reynolds Governor’s Cup Small Business Division at the April 2013 Awards Dinner (Oklahoma). Their entry used nano-wire technology to extend cell phone battery life by harnessing energy from the voice of phone users and background noises. “EchoCharge” was from the University of Tulsa, led by Katherine Sind, and advised by Claire Cornell. Those considering designing a self powered or self charged version of Moving Propeller Alert System might find this project useful.

If any body is interested in pursuing a Senior Design project in this area, please contact us. Also, please see our page listing several other possible Sr. Design Projects in propeller safety.

The moving propeller alert is a patented product.

I looked around and see no Brunswick patents or patent applications applying specifically to their Moving Propeller device. Brunswick may have filed a patent application and paid additional funds to prevent the application from being printed at 18 months, so it is possible one is still working its way through the system. However a search for patents or patent applications assigned to Brunswick pertaining to several mixes of the following terms failed to turn up anything similar to Moving Propeller: propeller, light(s), LED, rotating, and boat.

At any rate, Moving Propeller uses a CAN bus system. It operates on Mercury Marine’s bus / network that ties many gauges, the engine, and other electronics together. Mercury calls their CAN bus network, SmartCraft. A stand alone system as described in this post would not be tied to SmartCraft or any other network and thus would be far different from any patent for the Mercury’s Moving Propeller device.

Brunswick / Mercury Marine may think their CAN bus patent, U.S. Patent 6,273,771, applies to their Moving Propeller device. The patent teaches tying many boating systems together on the network. We make no judgement as to whether Moving Propeller is covered or not, but even if it is, 6,273,771 is a CAN bus patent. It has nothing to do with stand alone systems.

CAN bus has been applied by countless industries to network vehicle onboard sensors, gauges, engine controllers, and other components allowing some tremendous things to happen, but they cost money. For example, Mercury sells just the parts for a Moving Propeller kit for about $315 and that is in addition to the cost you paid to have SmartCraft in your boat. In contrast, it might be possible to manufacture an economical stand alone system for this specific application for less than $10 in volume.

If anybody is aware of a Brunswick patent that more specifically applies to Mercury Marine’s Moving Propeller, please let us know.

Thanks for your comment.

gary

3 April 2013 Update – U.S. Patent 7,247,063 Warning Device for Marine Engines for Small Craft. by Marc Lemchen. Detects when the propeller is rotating and warns people in the water. Mercury may have licensed this patent. If not, Mr. Lemchen might want to hire some legal help to see if Mercury’s device infringes on his patent or not. At a quick reading, the first claim of Mr. Lemchen’s patent appears like it might “read on” Mercury Marine’s device.