Propeller Guard Designed for Courtroom Use – Senior Design Project

The boating industry continues to reject the use of propeller guards and vehemently testifies against them in propeller injury trials. One of their tools is to illustrate ANY changes in the performance of the boat with the guard vs. without the guard and claim those changes are unacceptable.

We propose a Senior Design Project, Capstone Project, or Senior Thesis in which students develop a propeller guard that provides at least some level of protection while absolutely not changing the performance of the boat and not causing any other unintended consequences. This Senior Design Project might particularly appeal to student in mechanical engineering students, marine engineering, ocean engineering, design, CAD / computer aided design, safety, or law.

In real life, propeller guard designers design guards to maximize protection while minimizing the guard’s impact on the performance of the boat. They typically end up with a prop guard that provides good protection, but one or more element of boat performance is at least measurably impacted (top speed, time to plane, handling, steering, performance in reverse, durability, increased potential area for blunt trauma, entrapment in the guard, fuel consumption, emissions, porpoising, draft, weeds/sea grass, ability to speed to shore after an accident, cavitation, etc.)

Guard designers think it is a very good tradeoff (get great protection but boat goes a couple miles and hour slower, etc.), however the boating industry uses that delta (change in one or more boat performance variable) as a reason to reject the propeller guard.

If your guard makes any change at all the performance of the vessel, the industry turns Robert Taylor, their legal boat performance expert loose on it, with his three dimension GPS with its base station and his 3 axis of rotation recorder, along with his video recorders, steering torque pickup, and other sensors. Mr. Taylor will document the differences in the same boat with and without your propeller guard. They will find the specific environment and actions that amplify those differences (such as in a high speed turn, in reverse, or in shallow water) and will “prove” to a jury those differences make your guard unacceptable.If your guard hangs down in the water, they turn Kelly Kennett, the industry underwater impact and blunt trauma expert loose on it. Mr. Kennett (or his replacement after some compromising comments indicating bias by his technicians were overheard in a video recording used in Listman vs. OMC) will document the impact of pieces of your prop guard striking lamb skulls in water and claim if you hit a person at 3 mph or more, they could suffer a skull fracture.

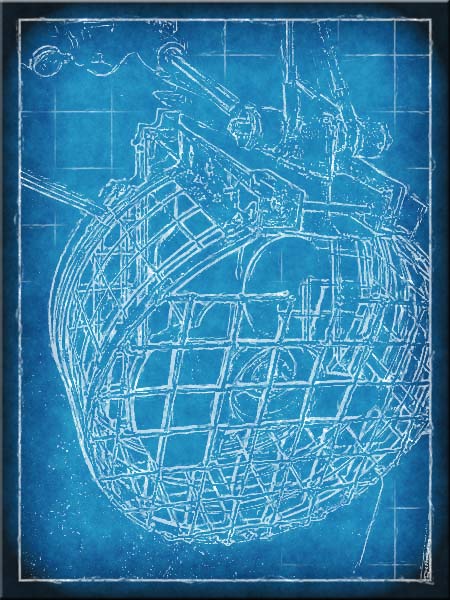

Mr Kennett will also illustrate how people can enter your guard and be entrapped, like the nice snapshot they took of somebody feeding this pretty little girl into a propeller guard in the Listman Trial (photo courtesy of Courtroom View Network.Our suggestion is to design a propeller guard that may not provide great protection, but when mounted on a boat, the boat performs EXACTLY like the same boat without a guard on it and creates no unintended consequences. In addition the guard provides no opportunity for entrapment and the guard is not in the water above 5 miles per hour or cushions impacts if it is.

The Courtroom Propeller Guard would provide some protection to the rear when the drive is started and when backing up, both of which are common situations in propeller accidents.

The goal is NOT to develop a propeller guard for sale. It does not need to provide maximum protection. Like many pharmaceuticals, it may only protect 20 percent of the people, but unlike pharmaceuticals, the Courtroom Propeller Guard has absolutely no side effects and no unintended consequences.

In addition the guard is reasonable in cost, is manufacturable, very durable, and can in no way damage the propeller or drive.

The goal is NOT to get the propeller guard into production. Its only life would be in the courtroom The guard could be used to force the industry to put propeller guards or other safety devices on certain at risk boats. For example the plaintiffs would ask drive companies why they are not using the device that has no downsides, prevents 25 percent of all propeller accidents, and only costs $50.

Once the industry caved, they would either copy your guard and use it or move to more conventional propeller guards and other propeller safety devices in those applications and try to minimize their downsides. You could try to patent your guard if you want, but it will be very difficult to keep the industry from changing it a little bit and copying it anyway, unless you have some super unique feature.

Some possible elements of a Courtroom Propeller Guard include:

- Flip up guards (flip up when underway)

- Retractable guards

- Guards made from “kevlar like” netting

- Guards that automatically deploy just before impact (like air bag guards)

- Smart materials that change shape or stiffness characteristics

- Throw away guards like goggle covers on jockeys except these automatically shed and deploy

- Sort of a line guard for people (some props have devices to try to keep fishing lines out of them)

- Instant propeller brake like the table saw SawStop fuse but it has an auto reset

- Special propeller designed to keep people out of it and minimize injuries (some design approach different than that taken by the Australian Environmental Safety Propeller)

- Fluid guards (water pushes you out of danger)

- Somehow causes the drive to slip for a few seconds in reverse before it begins to pull in water providing a few second window for the operator to kill the engine after someone yells

We suspect some outside the box thinking might result in ways that can provide some protection, while not changing boat performance. We are not interested in guards that require individuals to wear some special item in order to be saved.

While thinking outside the box you may actually generate some propeller safety innovations that could really hold their own in the real world. You’ll never know unless you try.

In terms of performance as a propeller guard, this is where you can let down your design criteria. As long as it protects some people and causes no harm, its great. For example, the Courtroom Propeller Guard might:

- Only works in certain environments (freshwater, sunlight, cold water, etc.)

- Dissolves away, be very fragile, need replaced now and then, but when the moment comes it does great job

- Only protect a certain element of the population (kids, adults, women, males over 100 pounds, etc)

- Protect only a portion of the danger area such as the perimeter of the blade or a portion to the rear

We are not asking you to design a guard that provides minimal protection, we are asking you to design a guard that provides no measurable impact on the boat or normal operations. In doing so, you will probably have to reduce protection in some areas or situations. The people that do get past you guard will be injured by the propeller exactly the same as they would be if your guard was not present.

If you happen to come up with a guard that has no measurable impact on boat performance, has no downsides, and does not reduce protection in some areas or situations, you need to call a patent attorney.

If you are interested in talking on a Senior Design Project, Senior Thesis, or other similar project of this nature, please contact us.

We would also welcome hearing from anybody that might be interested in sponsoring a design contest of the nature of the Boat U.S. life jacket design contest for propeller guards (or propeller safety devices) that do not impact the performance of the boat or create other downsides.